When we install a new boiler we diagnose the entire system. This includes the production of heat and distribution of heat.

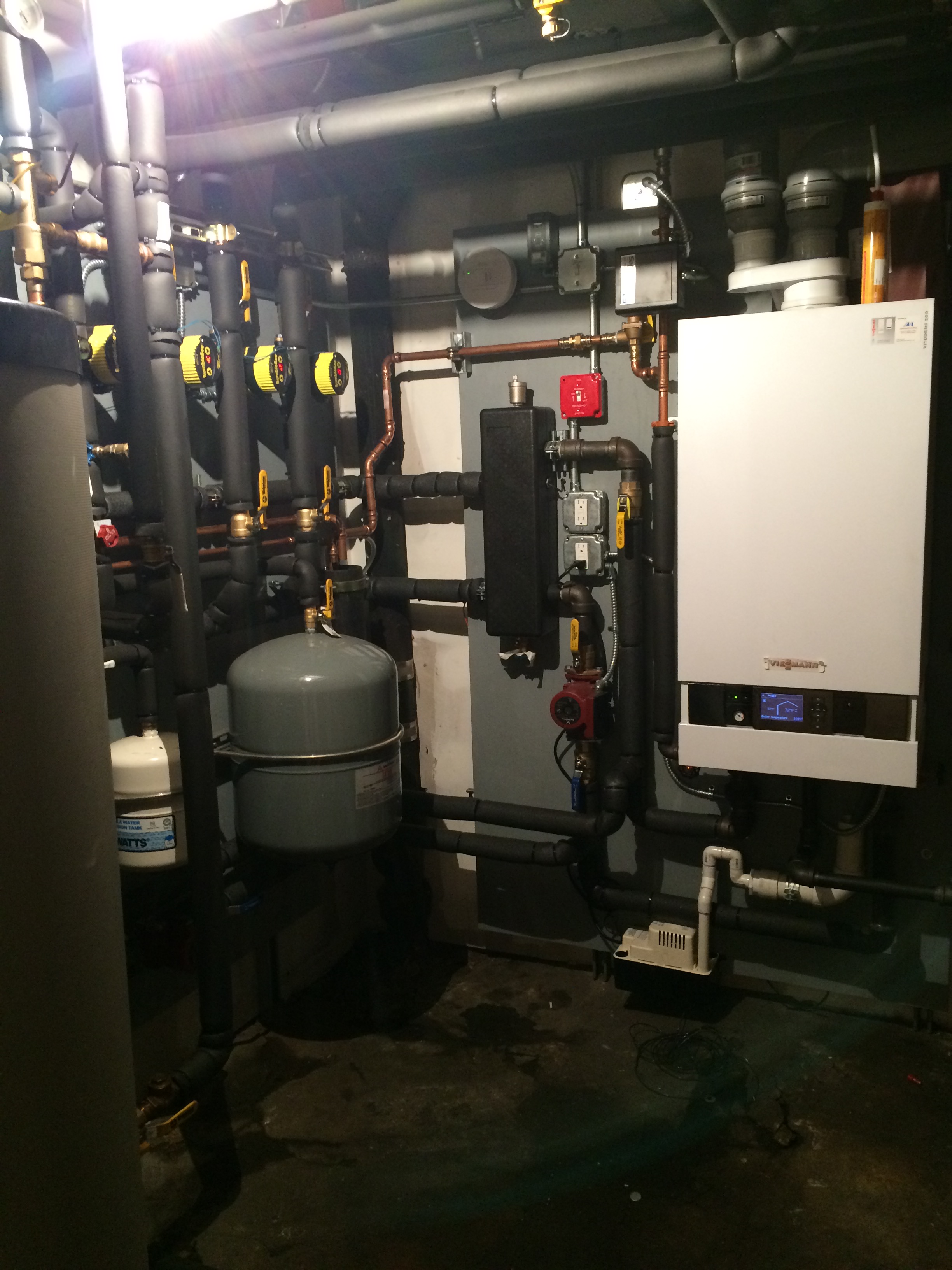

We want to make sure that each stage of the heating process is done correctly and efficiently. This includes the boiler (sizing, cleaning, installation, supports, etc); near boiler piping (all the piping within 15' of the boiler will be completely brand new, in the proper configuration, and insulated); boiler controls and devices (all the controls will be brand new and the latest technology); production of hot water in a manner that makes sure there is no loss of energy; installation of master vents to make sure that the boiler is not operating to produce pressure to push steam but that steam flows through the system entering each radiator at the exact same time; TRVS on all the radiators to dynamically adjust their output based on the conditions of the room; and the redlink to determine the buildings indoor conditions (if the coldest area is satisfied then no more heat is needed).

Our steam systems are unlike any in New York. An installation by Absolute Mechanical ensures that there will be no more steam hammer noise, no more over heating or dips in temperature, and no more dry air.